SEATTLE — This week Governor Jay Inslee called on manufacturers to re-tool and try to make some of the personal protective equipment (PPE) that Washington state desperately needs to fight the coronavirus. Items like surgical gowns, face shields, and saline solution.

Before Gov. Inslee even asked, one of the area's biggest manufacturers had already answered the call.

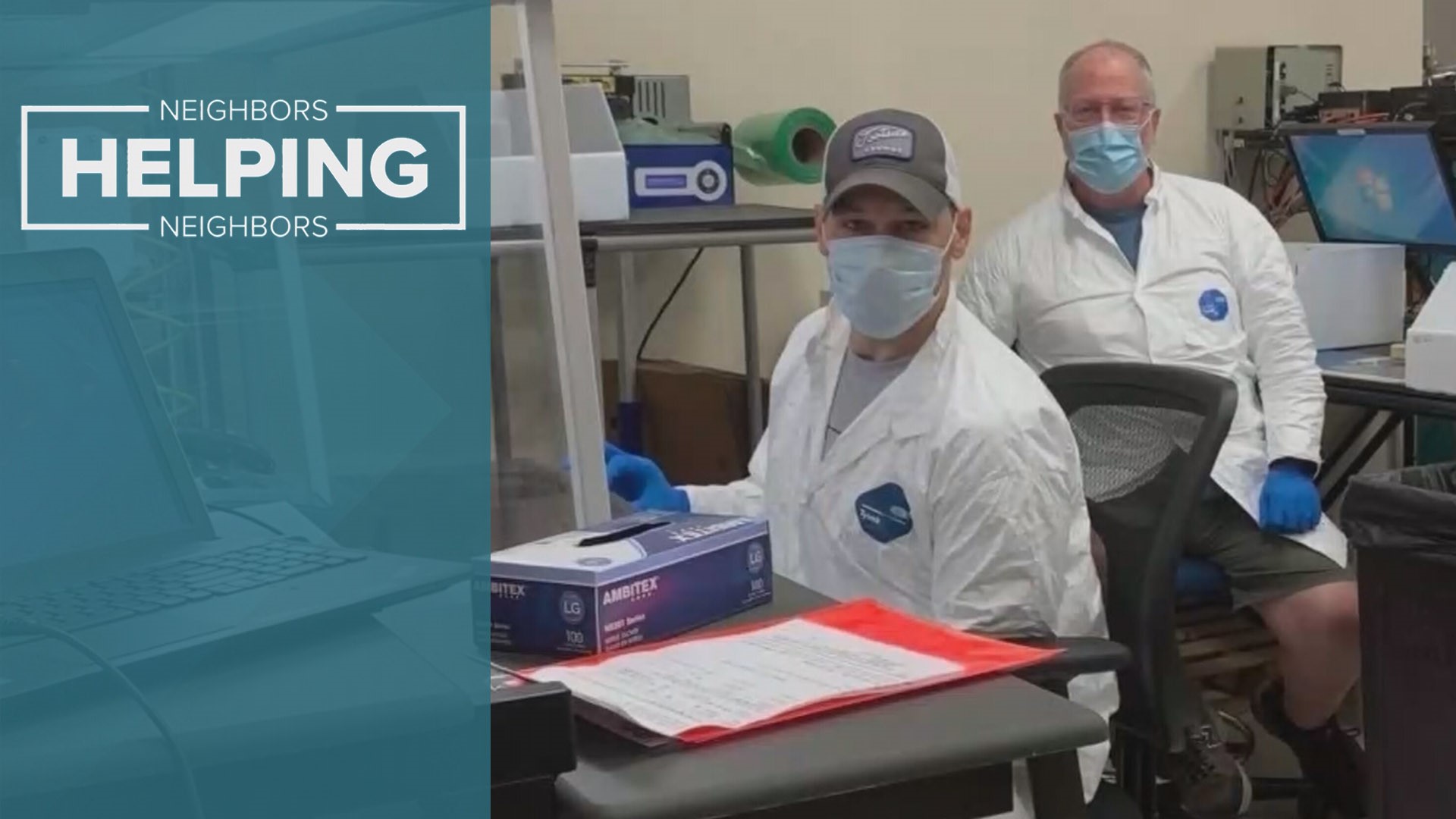

GM Nameplate, the largest privately held manufacturing business in Seattle, does work with Boeing and several other companies around the world.

When they heard that medical workers on the front lines were making their own face shields, company President Brad Root knew they could help.

“I saw this and I said ‘wow we could be making this for them,' our company does custom manufacturing of a lot of different things so this was pretty natural for me,” he said.

They quickly came up with prototypes and asked nurses at Swedish hospital to test them. "Literally, it went from prototype to production within a matter of days,” Root explained.

The company has made some medical products, but nothing like this, Root explained. He said they moved some resources from their aerospace production to start getting the face shields done. He also said employees have been excited to help out.

“We had people motivated to come into work and support the cause, we had people who were planning on being on vacation who decided 'no we're going to cancel,' because they would rather come in and help make face shields and protect the frontline workers out there,” Root explained.

The company has donated some of the face shields to hospitals and nursing facilities and they're getting the rest out into the marketplace. By the end of this month, they hope to have 200,000 done and they’ll keep increasing production as long as the need is there.

“We're going to continue on doing face shields we have people in our office staff starting to be part of a production line and I spend a few hours every night doing that,” Root said. They shared information about their production changes with other manufacturers in their industry and hope they can keep making a difference.